“Valves”

Valve is a mechnaical device that regulates, directs & controls the flow of fluid (Liquids, Slurries or Gas) by opening, closing or partially obstructing the

various path ways.

Valves plays a very significant role starting from a water tap in our house to the high-tech ignition of a rocket engine.

Even the survival of human life will be at stake if the heart valves stops controlling the blood circulation.

Estimates reveal that a substantial portion, approximately 10-12 % of the Piping expenditure of the chemical process industry is used for procurement of

valves and fittings.

Proper care needs to be taken for the selection of valves.

The first step in the selection of valve is to determine exactly what function one is expected from the valve.

The design of the valve is done in such a way as to perform any of the Isolation, Regulation, Non Return or some special function as needed by the process

industry.

Types of Valves:

Based on functions: a)Isolation Valves : Gate , Ball , Plug, Butterfly b)Regulation Valves: Globe , Needle , Butterfly c)Non Return Valves: Check valve Based on End Connections: a) Butt Welded b)Flanged c)Screwed d)Socket weld

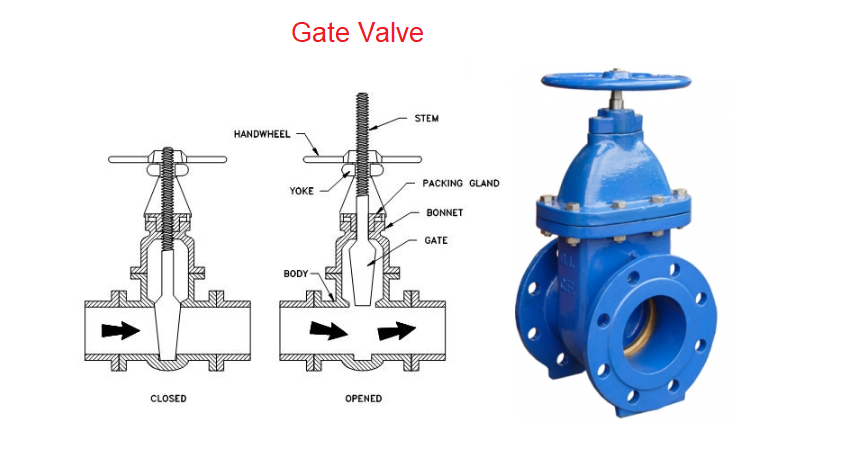

Gate Valves: Gate Valves are basically designed either to start or stop the flow. when used in service, these valves generally are either fully open or fully closed. The disk of a gate valve is completely removed when the valve is fully open; the disk is fully drawn up into the valve bonnet. This leaves an opening for flow through the valve at the same inside diameter as the pipe system in which the valve is installed. A gate valve can be used for a wide range of liquids and provides a tight seal when closed. Advantages of using gate valves: Good shutoff features. Gate Valves are bidirectional and therefore they can be used in two directions. Pressure loss through the valve is minimal. The major drawbacks to the use of a gate valve are: They cannot be quickly opened or closed. Gate Valves are not suitable to regulate or throttle the flow. They are sensitive to vibration in the open state.

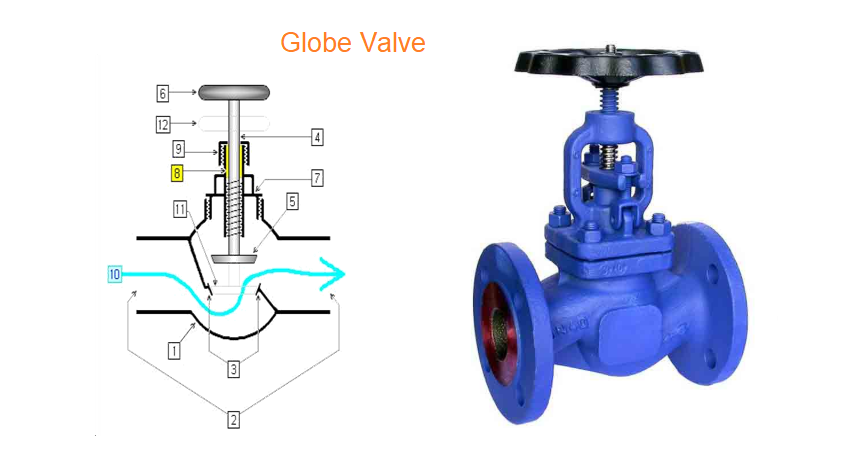

Globe Valves: A globe valves is a linear motion valve and are primarily designed to stop, start and regulate flow. The disk of a globe valve can be totally removed from the flowpath or it can completely close the flowpath. The fundamental principle of the globe valve operation is the perpendicular motion of the disk away from the seat. This ensures that the ring shaped space between the disk and seat ring gradually close as the valve is closed. This property gives a globe valve reasonably good throttling capability. Therefore, the globe valve can be used for starting and stopping flow and to regulate flow. Advantages of using globe valves: Good shutoff capability. Reasonably good throttling capability. The major drawbacks to the use of a globe valve is: The Significant pressure drop across a fully open valve and they do not provide a bubble-tight seal.

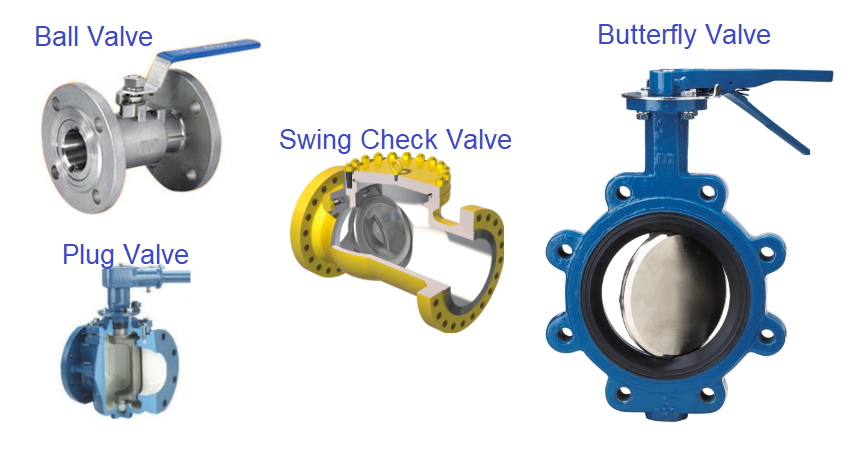

Ball Valve: A ball valve is a quarter‐turn rotational motion valve that uses a ball‐shaped disk to stop or start flow. If the valve is opened, the ball rotates to a point where the hole through the ball is in line with the valve body inlet and outlet. If the valve is closed, the ball is rotated so that the hole is perpendicular to the flow openings of the valve body and the flow is stopped. Advantages of using ball valves: Quick quarter turn on‐off operation. Tight sealing with low torque. Smaller in size than most other valves. Disadvantages of ball valves: Conventional ball valves have poor throttling properties .In slurry or other applications, the suspended particles can settle and become trapped in body cavities causing wear, leakage, or valve failure.

Plug Valve:

A plug valve is a quarter‐turn rotational motion valve that use a tapered or cylindrical plug to stop or start flow. In the open position,

the plug passage is in one line with the inlet and outlet ports of the valve body. If the plug 90° is rotated from the open position, the solid

part of the plug blocks the port and stops flow. Plug valves are similar to ball valves in operation.

Advantages of using plug valves:

Quick quarter turn on‐off operation.

Minimal resistance to flow.

Smaller in size than most other valves.

Disadvantages of plug valves:

Requires a large force to actuate, due to high friction.

Butterfly Valve:

A butterfly valve is a quarter‐turn rotational motion valve, that is used to stop, regulate, and start flow. Butterfly valves are easy and fast to

open. A 90° rotation of the handle provides a complete closure or opening of the valve. Large Butterfly valves are usually equipped with a so called

gearbox, where the handwheel by gears is connected to the stem. This simplifies the operation of the valve, but at the expense of speed.

Advantages of butterfly valves:

Compact design requires considerably less space, compared to other valves.

Light in weight.

Quick operation requires less time to open or close.

Available in very large sizes.

Low pressure drop and high pressure recovery.

Disadvantages of butterfly valves:

Disc of the valves block the flow passage.

Cavitation and choked flow are two potential concerns.

Disc movement is unguided and affected by flow turbulence.

Check Valve: Check valves are "automatic" valves that open with forward flow and close with reverse flow. The pressure of the fluid passing through a system opens the valve, while any reversal of flow will close the valve. Exact operation will vary depending on the type of check valve mechanism. Most common types of check valves are swing, lift (piston and ball), butterfly, stop and tilting disk.

Function-wise categories of Valves: On-off Valves : Gate, Ball, Plug, Butterfly, Diaphragm. Flow regulation : Globe, Butterfly. Non-return valves : Check. Sampling Valves : Globe,Needle,Plug,Special Sampling Valves.

Design & Testing Standards of Valves: Type of Valve Design Standard Testing Standard Gate < 2” API-602 API-598 > 2” API-600 API-598 Globe < 2” BS 5352 BS 6755 > 2” BS 1873 BS 6755 Check < 2” BS 5352 BS 6755 > 2” BS 1868 BS 6755 Ball BS 5351 / API 6D BS 6755 / API 607 Plug BS 5353 BS 6755 Butterfly BS 5155 / MNF STD. BS 6755

Procurement Cycle: CS valves: For small bore : 3 months FOT site. 2”-24”: 4-5 Months FOT site. > 24”: 7 Months FOB & 8 months FOT DP. AS &SS (Large Bore): 5 Months FOT site. Butterfly Valves: 4-5 Months FOB. Ball Valves: 4 Months FOT site.

Inspection of Valves:

Magnetic Particle Inspection : For inner cracks.

Die Penetration Test : For surface cracks.

Radiography : Total NDT.

Impact Test : For LT Services.

Strip Check Test : To check internals.

Positive Material Identification.

Inter Granular Corrosion Test (For SS Only).

Case Study:

Let's consider an application in a chemical processing plant where a valve is needed to control the flow of a corrosive chemical through a pipeline.

The chemical requires precise flow control, and the valve needs to be resistant to corrosion.

Selection Criteria:

In this case, a plug valve could be a suitable choice. It offers excellent corrosion resistance due to its material options (e.g., stainless steel or

lined plug valves). The quarter-turn operation allows for quick on/off control, and some plug valve designs can also provide moderate throttling

capability for precise flow control.

By understanding the specific requirements of the application and matching them with the characteristics of plug valves, you can determine that a

plug valve is appropriate for this scenario.

It's important to note that the selection of the right valve for any application should be done by experienced engineers or valve experts who can

take into account all relevant factors to ensure safety, efficiency, and optimal performance in the specific process.